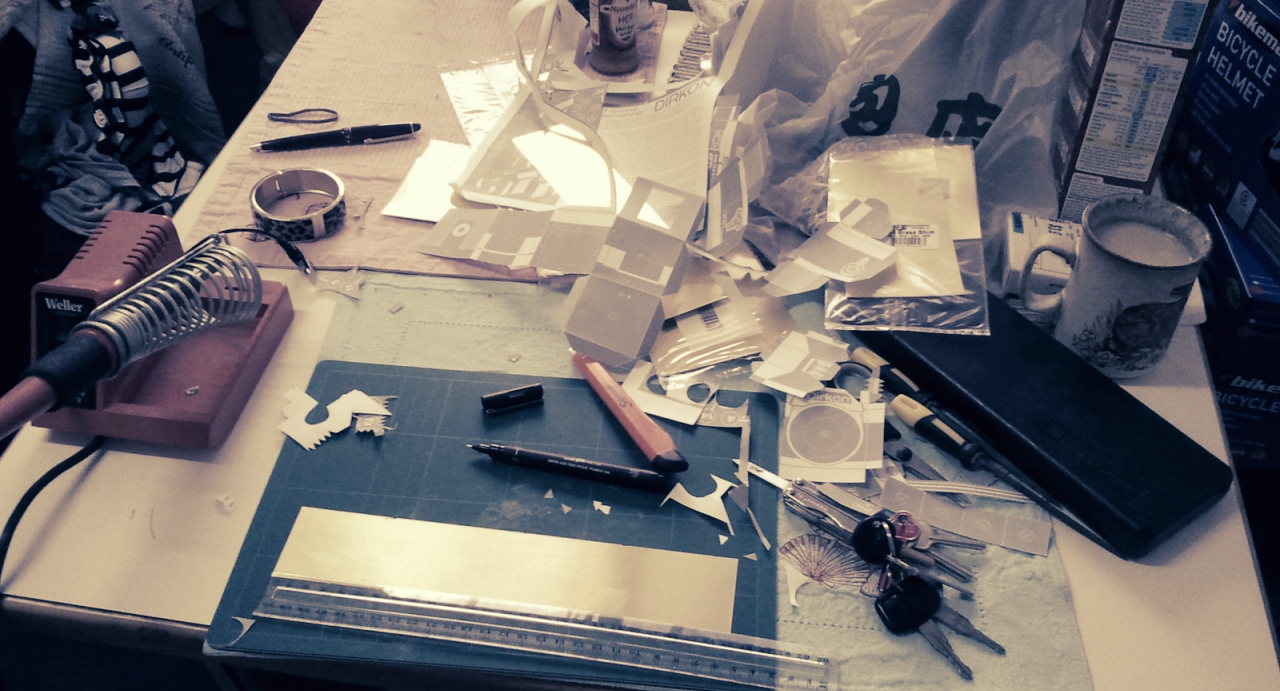

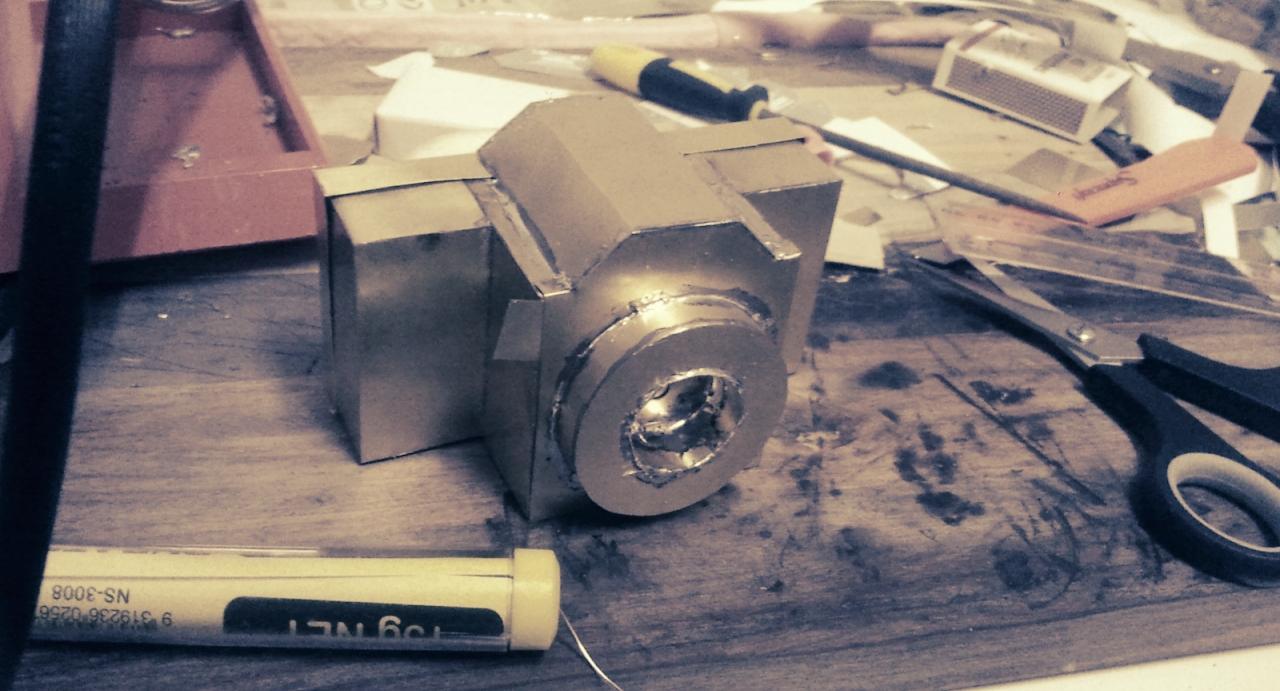

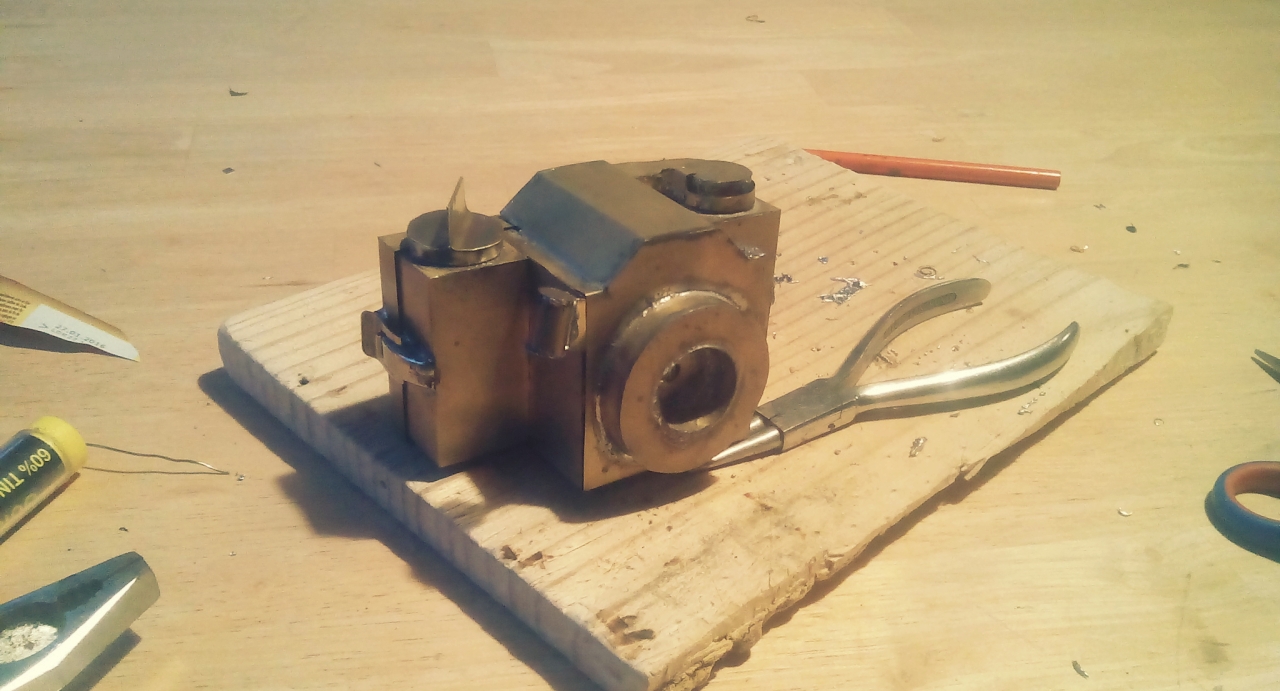

I saw a cardboard pinhole camera in a shop window on the way home one night, for some reason the thing really appealed to me. After some googling I saw the Dirkon pinhole camera and found the design to be insanely cute, however cardboard seemed insanely flimsy and in no way painful enough to construct…. bring on some packets of brass shimming, solder and a large soldering iron.

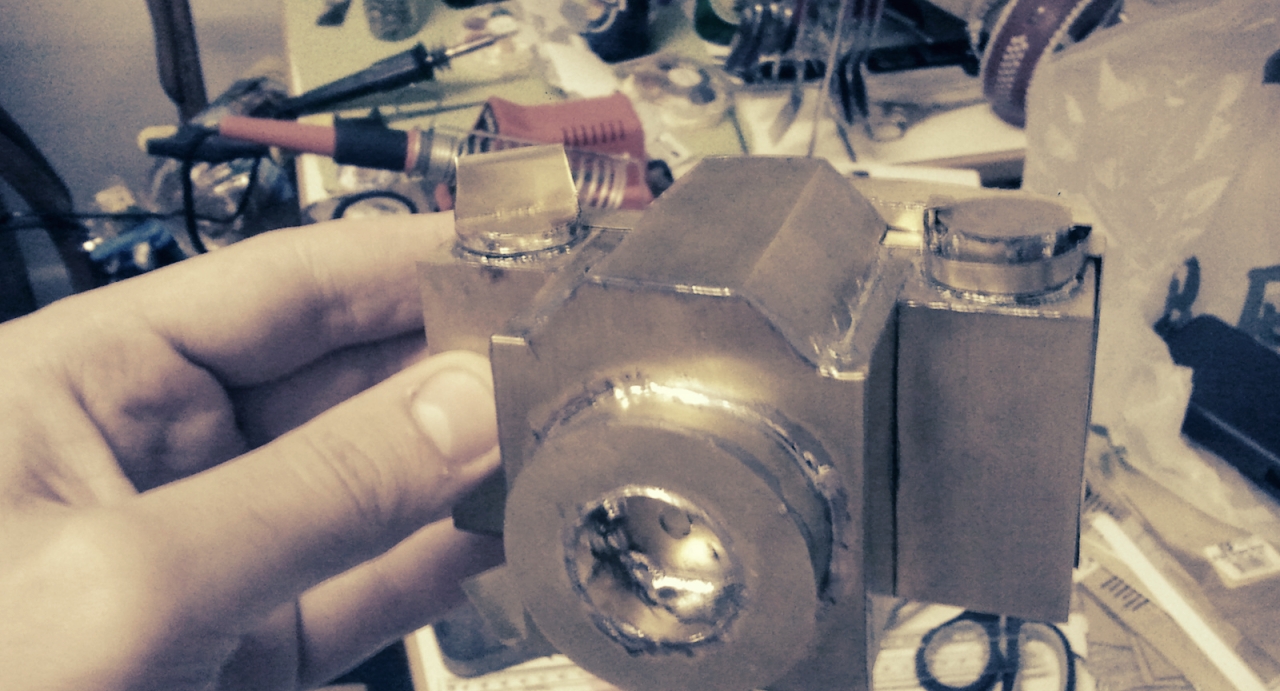

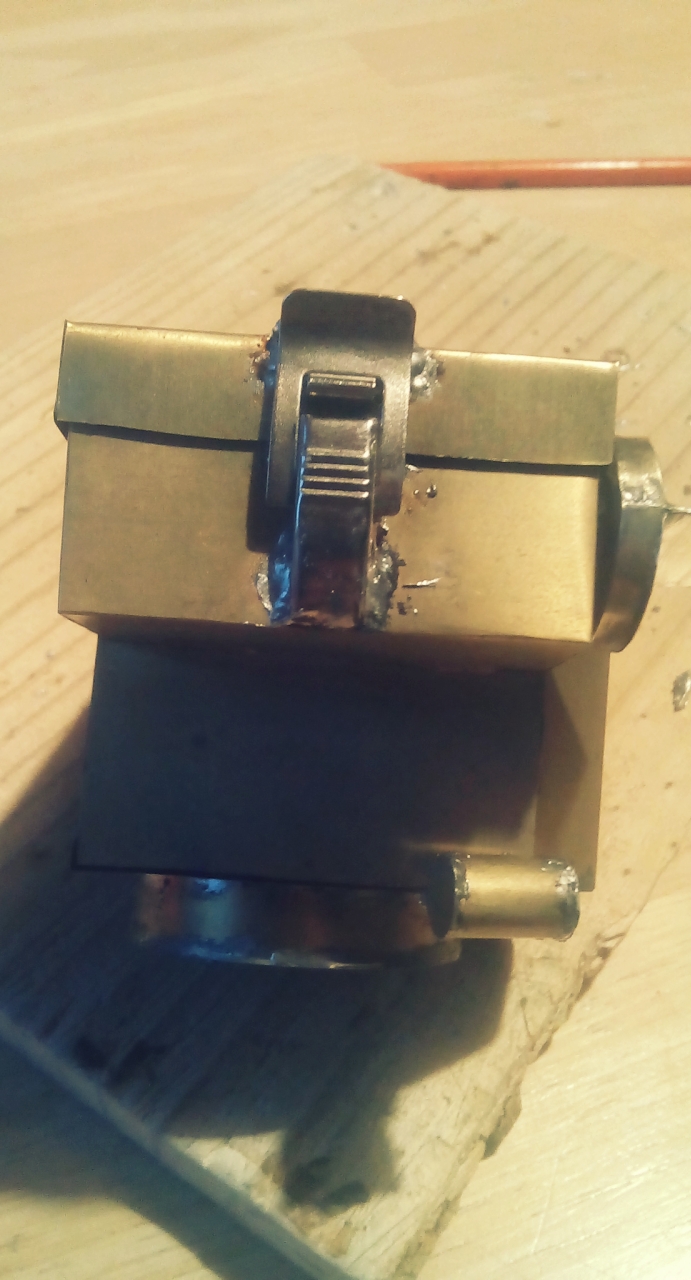

Copying the Dirkon template in brass had proven much quicker and easier than expected, so I decided to complicate life by adding a ratcheting film advance lever.

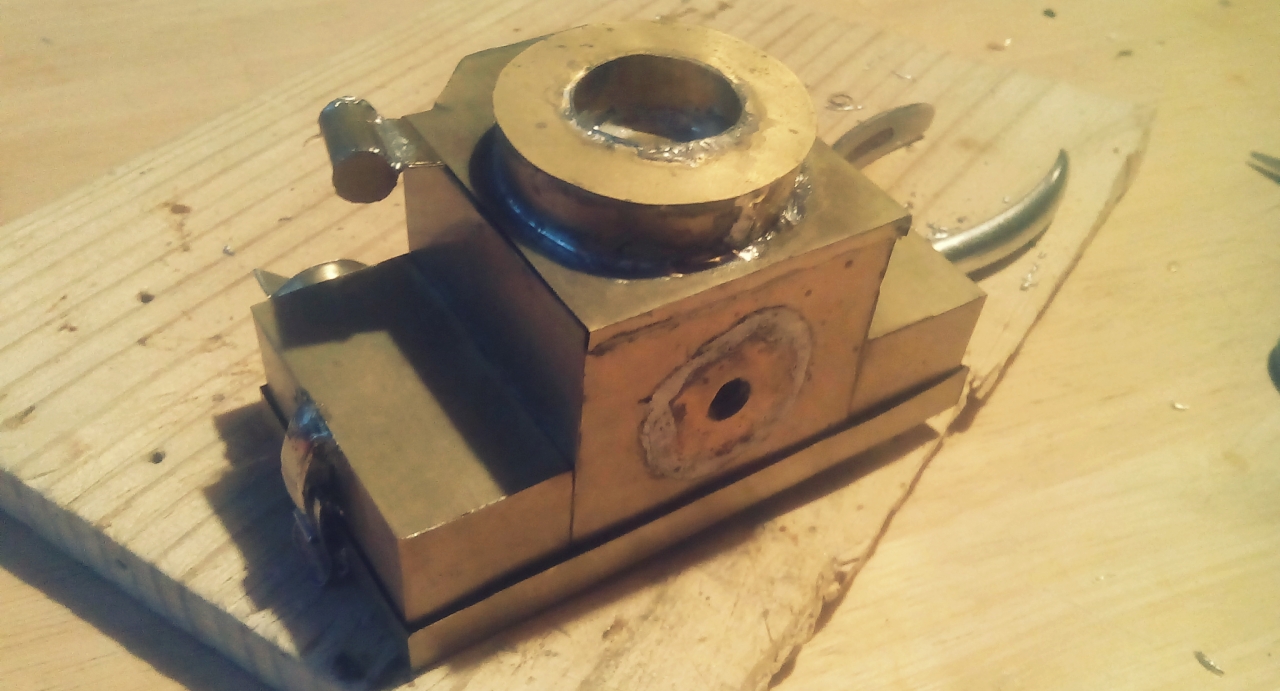

I then soldered a small reinforcing plate onto the bottom of the camera body then soldered a 1/4″20tpi UNC nut on the inside of the camera body, with a small plate over the top to light proof it. This makes the whole thing tripod mountable which is very handy for the long exposure times that pinhole cameras require.

Some little latches from a novelty tin lunchbox that I found in an opp shop fitted perfectly onto the sides and saved me from having to engineer something out of brass.

The next step was light proofing the whole thing, for the back I bent up a black cardboard insert that fitted snugly inside the brass back, the edges were doubled over so as to provide tension around the camera body, the inside of the camera was painted with black matte black enamel so as to eliminate any internal reflections from the brass.

For the film I intend to use cheap ISO 200 B&W stock from my fastloader, so I will be using refillable canisters, this allows me to invert the spindle on one canister so that the film remains parallel when feeding into the second receiver canister. I chose this configuration as it limits light damage to only one and a half frames should I forget that it is loaded and open the back.

It is just a matter of carefully making the hole with the tip of a pin that has been sharpened to have a flat side, then smoothing the edges of the hole out with fine emery, repeating the process a few times will make a very clean hole.